1.Speed Client/Server Transfer

Incidents: 17359, 20948

PanaPRO now supports an automated process that allows you to schedule, compress, and reindex jobs while improving the efficiency of transferring large amounts of data between the client and server. You can now schedule a “compress and reindex” event for data through the Add Schedule Task function in the Windows Control Panel, as follows:

To Schedule a Compress and Reindex:

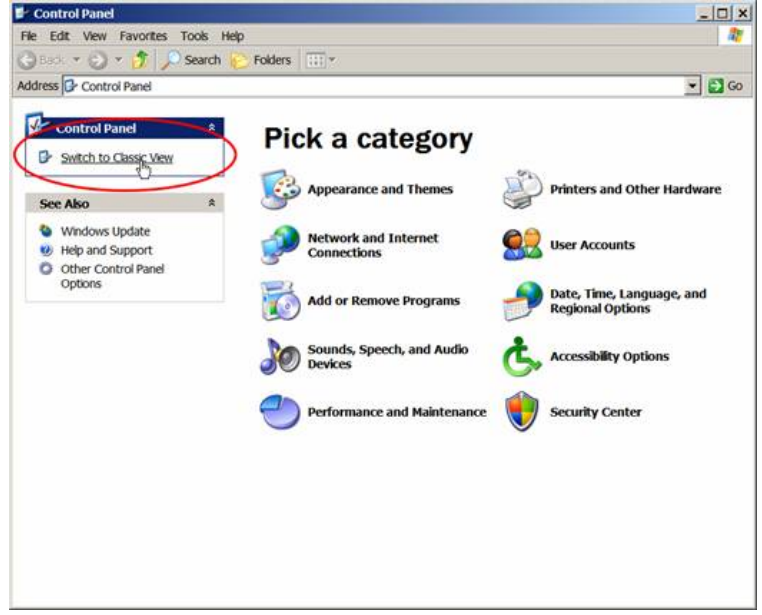

- Navigate to Windows Control Panel.

- If you are in Category View, click “Switch to Classic View”.

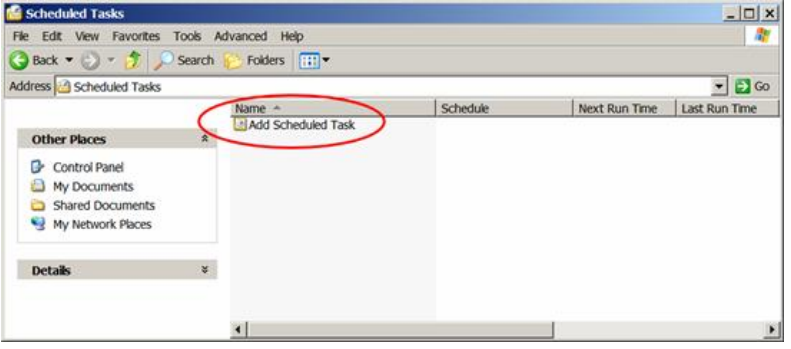

- Double-click on Scheduled Tasks.

- Double click on Add Scheduled Tasks to open the Scheduled Task Wizard.

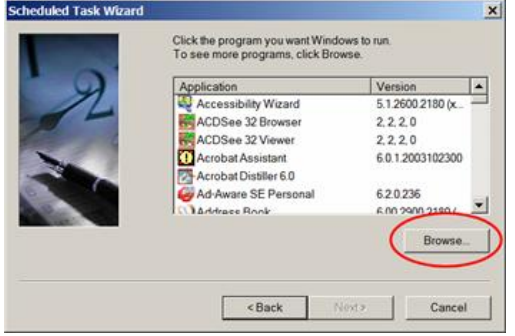

- Click the Next button.

- Click the Browse… button.

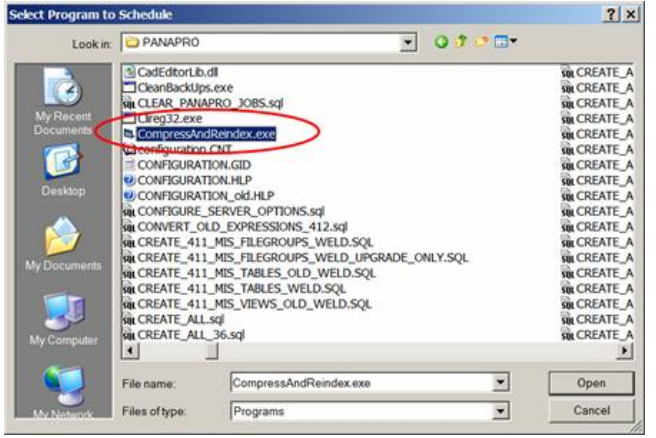

- Navigate to pfauser\pfaprog\panapro and choose compressAndReindex.exe.

- Select a frequency to run the tool. It is recommended that this job be scheduled daily. Then, click the Next button.

- Select a time to run the tool. It is recommended that this job be scheduled at a time when PanaPRO activity is at its lowest point. Note that this is a background job which will not interfere with the regular PanaPRO activity. Then, click the Next button.

- Enter the name and password of a user on the computer, who has permission to run the job. The task will run as if it were started by that user. Then, click the Next button.

- Click the Finish button to complete scheduling.

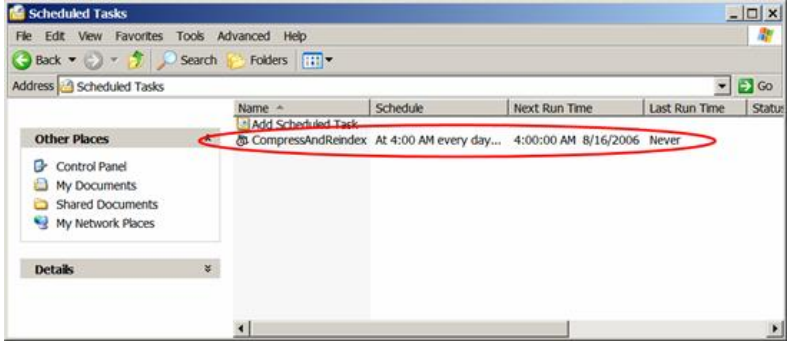

The task now shows up on the scheduling list.

2.Nozzle Editor Enhancements

Incidents: 20356, 20357, 20358, 20359, 20361, 20444, 21123

Enhancements to the Nozzle Editor include:

- Nozzle positions expand and center when the screen resolution changes or when you resize the Nozzle Editor.

- Head rules are validated. For instance, when a large 450 nozzle is assigned, the adjacent spindle positions are disabled. Assignment of a large nozzle also clears the adjacent assignments and disables the adjacent spindle location.

- The correct head configuration displays based on the Board Transfer Direction (Left to Right and Right to Left).

- Starting the Nozzle Editor at the cell level automatically highlights the selected table in the selected cell.

- A stop cursor displays when you drag an incompatible nozzle type from the inventory grid to a nozzle location.

- To maintain compatibility with existing Panasonic machines, the Configure Custom Nozzle dialog displays a checkbox when you select custom nozzles for a module.

- Individual head spindle or nozzle stocker locations can be disabled in the Nozzle Editor. This prevents the optimizer from using a location in the event of a problem, such as a broken nozzle or other mechanical failure.

3.CM602 Support for 12 Nozzles and Direct Tray

Incident: 21471

PanaPRO supports CM602 machines configured with 12 nozzles and direct tray support.

To add a 12-nozzle head:

- Open the Configure Options page for the CM602 in the Factory Explorer.

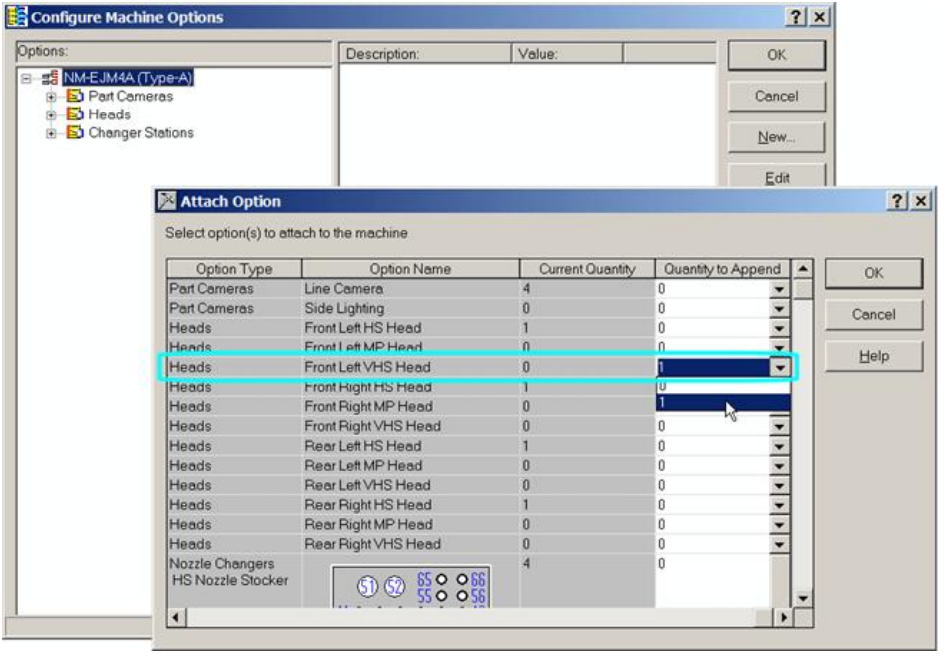

- In the window that opens, select the machine-level (such as NM-EJM4A) and click the New… button to attach a new option.

- Scroll through the list that appears until you find the appropriate head. 12-nozzle heads will have the label VHS (very high speed).

- Set the Quantity to Append field to 1 in the row of the head that you want to add.

Note: You can add multiple heads at the same time, by setting Quantity to Append in multiple rows. - Click OK. The new head(s) will appear in the tree structure on the left under Heads.

- Click OK to save your changes.

To add a direct tray, navigate to the Attach Option window, as explained in the steps above for adding a 12-nozzle head. Instead of finding a VHS head in the list, scroll to the Tray Elevators and change the Quantity to Append for a Direct Tray Elevator.

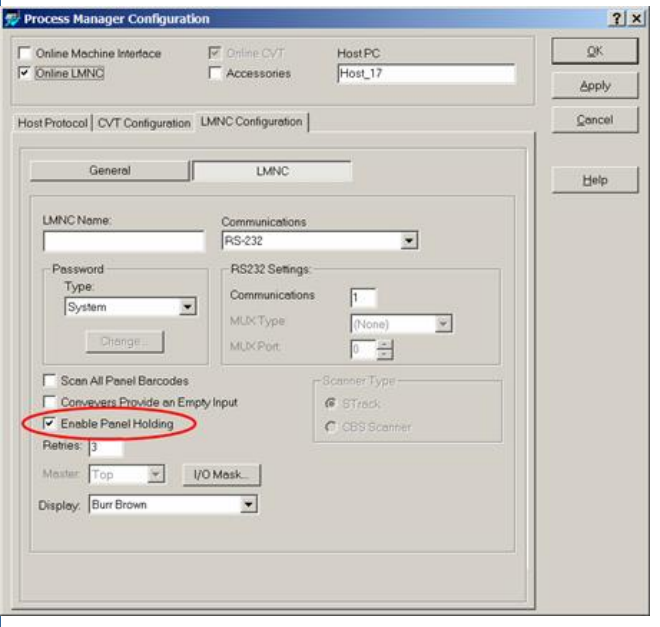

4.Enable Panel Holding For CM402

Incident: 21153

If you want to ensure 100% traceability, check the Enable Panel Holding checkbox on the LMNC Configuration tab of the Process Manager Configuration dialog. This option guarantees that the LMNC sends a unique barcode for each panel; the LMNC does not release a panel to the machine until it receives an acknowledgement from the host.

Note: This option is only available for CM402 machines.